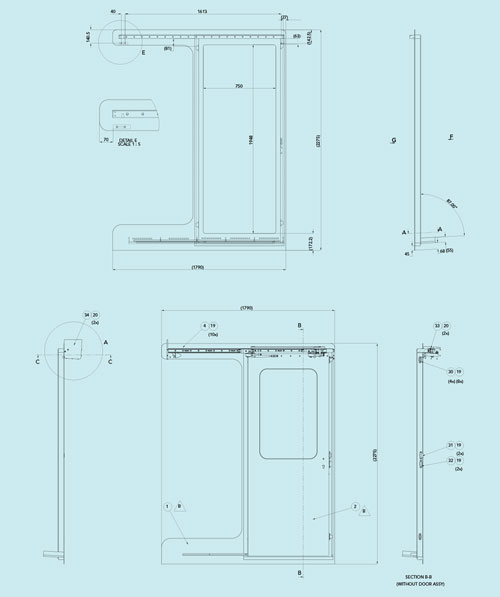

SUNRISE – Wheel House Sliding Door

Machined out of one piece of aluminium

- Very good looking, slim, flush and luxurious door

- Flush in closed position

- Manual operated

- Smooth cover plate without gaps for clips. The door is fitted out with locking pins instead

- Easy operation, because of the high quality guiding system which is fully integrated in the frame and door

- For your convenience and safety the door can be locked in several positions

- Very accurate, strong but lightweight construction

- ‘Plug and play’ – The door, the frame and the parts are fully assembled and tested in the factory and will be delivered ready for installation

- The door can be certificated by all major classification societies

Options and extra’s

- Opening left or right

- Double panel

- Night lock

- Electrical operation

- Remote Control

- Insulation

- Stainless steel frame

- Fully finished, with filler and paint

- Other dimensions than standard

- Certification

Slim and luxurious doors

Accommodation flush sliding door SUNRISE

Standard dimensions: Opening height 2000 mm. Opening width 1000mm.

Frame to be discussed with designer, depending on shape accommodation and space available.

Weight of the door and the frame: 150 kg including window.

Power supply: depending on ship’s system. Power consumption: 1,5 Kw maximum.

The door is CNC machined out of seawater resistance aluminium 5083. The frame is also of aluminium 5083 or alternatively stainless steel 316L. The door is a proven Newthex design. It is fitted out with high quality Newthex parts, a cover plate and a stainless steel pin central operated locking system. The door can be locked in several positions. When closed, the door is ush with the outer structure. Weather tightness is achieved by the Newthex special designed V- shape seal.

Sigmacover is applied at all aluminium parts. Stainless steel is pickled and passivated. Stainless steel parts in

sight are polished according ‘Mirror 8’. Galvanic corrosion protection is achieved by using TEF-Gel, Sika ex 291, Lexan insulation sheets and synthetic inserts wherever applicable. The door is designed in Solid Works 3D software and strength calculations are carried out with Cosmos Works. Door, frame, integrated guiding system, operating parts and cover plate are fully assembled, adjusted and tested in the factory. The door will be delivered within the frame and ready for welding into the ship’s structure. The door can be delivered with certificates of all

major classification societies.