BRIGHT STAR – Flush yacht hatch

Machined out of one piece of aluminium

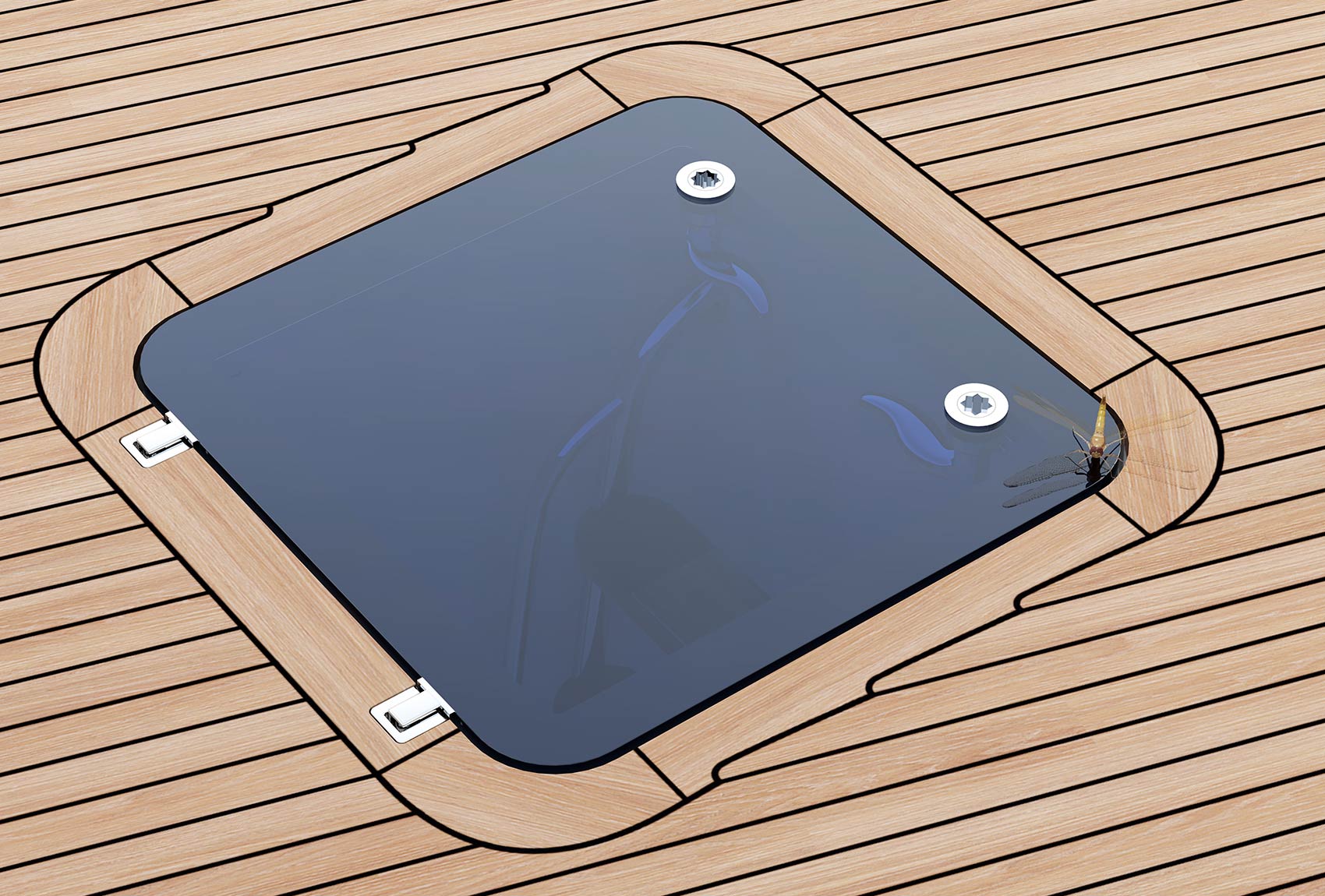

- Attractive design, slim, flush and luxurious hatch

- Strong but lightweight construction

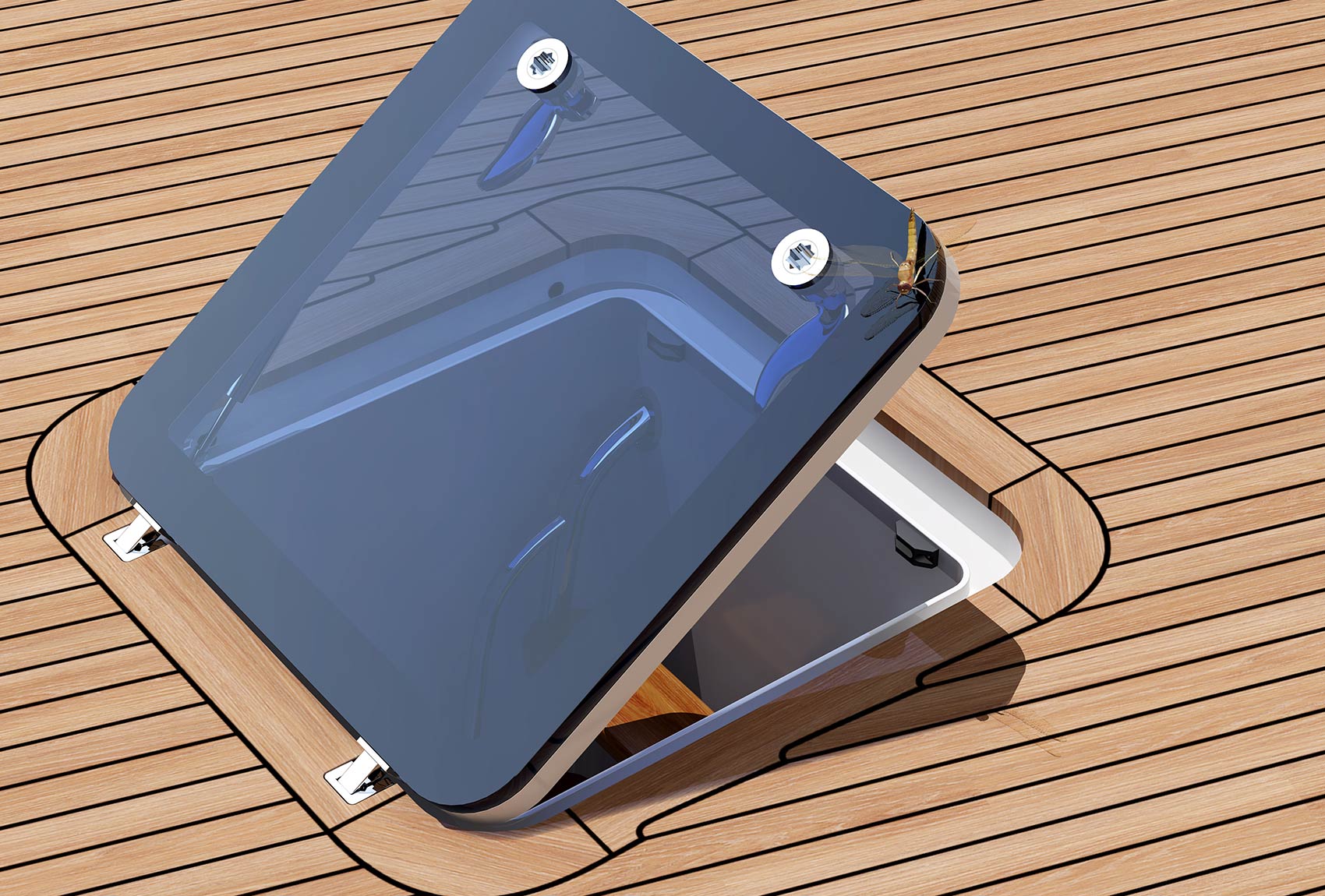

- Easy to operate

- ‘Plug and play’ – The hatch, the frame and the parts are fully assembled and tested in the factory and will be delivered ready for installation on board

- The BRIGHT STAR hatch has a CE marking and can also be certified by all major classification societies

Flush watertight yacht hatch with window

Flush watertight yacht hatch with window

Flush watertight yacht hatch with window

Options and extra’s

- Teak prepared version

- Bolted frame

- Shaped according the yachts deck form

- Certificate by a Classification Society

Shaped according yacht deck camber

BRIGHT STAR – Technical specification

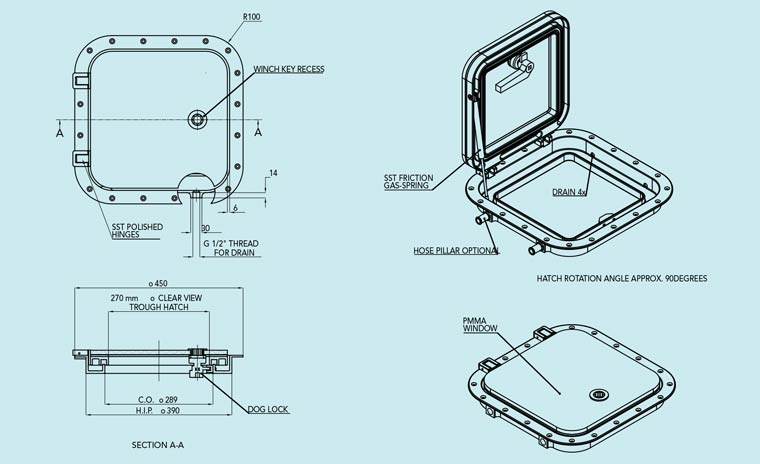

BRIGHT STAR hatches are CNC machined out of one piece of aluminium 5083. BRIGHT STAR hatches are out fitted with polished stainless steel heavy duty hinges, aluminium or stainless steel clips and a polished stainless steel gas spring with hold back function. The window is of Perspex 12 mm. (For hatches under classification glass will be used.) The BRIGHT STAR Hatch is powder coated. Galvanic corrosion protection is achieved by using TEF-Gel, Sika ex 291, Lexan insulation sheets and synthetic inserts wherever applicable.

The BRIGHT STAR Hatch is designed with Solid Works 3D software and strength calculations are carried out with Cosmos Works. Hatch, frame and operating parts are fully assembled, adjusted and tested in the factory. A BRIGHT STAR Hatch will be delivered within the frame and ready for welding or bolting into the yachts structure. Standard BRIGHT STAR hatches have CE marking, but can be delivered with certificates of all major classification societies also.

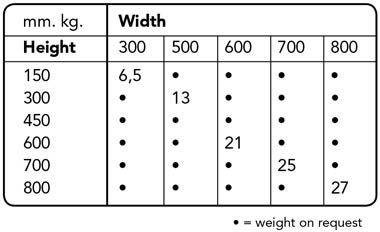

Standard dimensions ( clear opening ) and weights including frame: (Other dimensions on request)